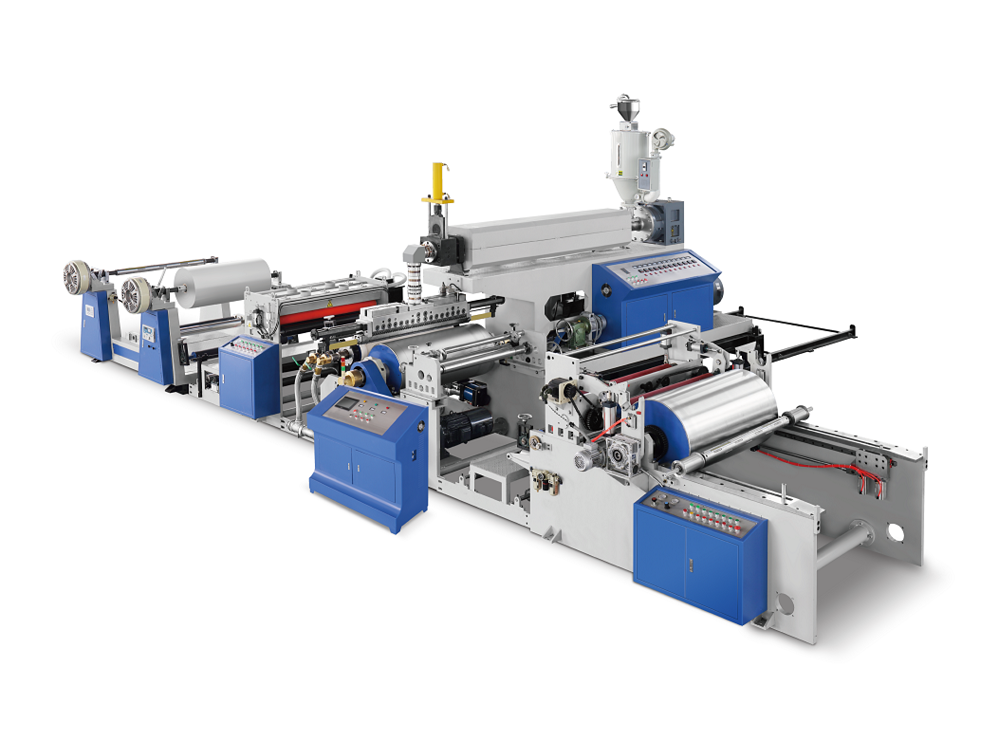

Co-Extrusion Lamination Machine SPLM1300/1700

It is designed at 210m/min line speed for flexible packaging films application. It works with LDPE, PP, EVA, EAA and acid copolymers at stable and high output rate.

Introduction

It is designed at 210m/min line speed for flexible packaging films application. It works with LDPE, PP, EVA, EAA and acid copolymers at stable and high output rate.

Technical Parameters

| Model | SPLM1300 | SPLM1700 |

| Screw Dia. (mm) | φ100 | φ105 |

| L/D | 33:1 | 33:1 |

| Finished Film Width (mm) | 600-1200 | 800-1600 |

| Lamination Thickness (mm) | 0.01-0.10 | 0.01-0.10 |

| Usable Resin (Coating Grade) | LDPE, LLDPE, PP,EVA, EAA | LDPE, LLDPE, PP,EVA, EAA |

| Design Line Speed (m/min) | 210 | 210 |

| Max. Extrusion Capacity (kg/h) | 300 | 330 |

| Main Motor Power Consumption (kW) | 45 | 55 |

| Total Power Consumption (kW) | 135 | 165 |

| Dia.of Main Unwinder (mm) | ≤φ1300 | ≤φ1300 |

| Dia.of Winder (mm) | ≤φ1300 | ≤φ1300 |

| Weight (t) | 11 | 13 |

| Overall Dimension(L×W×H) mm | 10000×9000×3200 | 12000×9600×3200 |

| Power Supply | 380/3/4/50(Volt/Ph/Line/Hz) | 380/3/4/50(Volt/Ph/Line/Hz) |

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

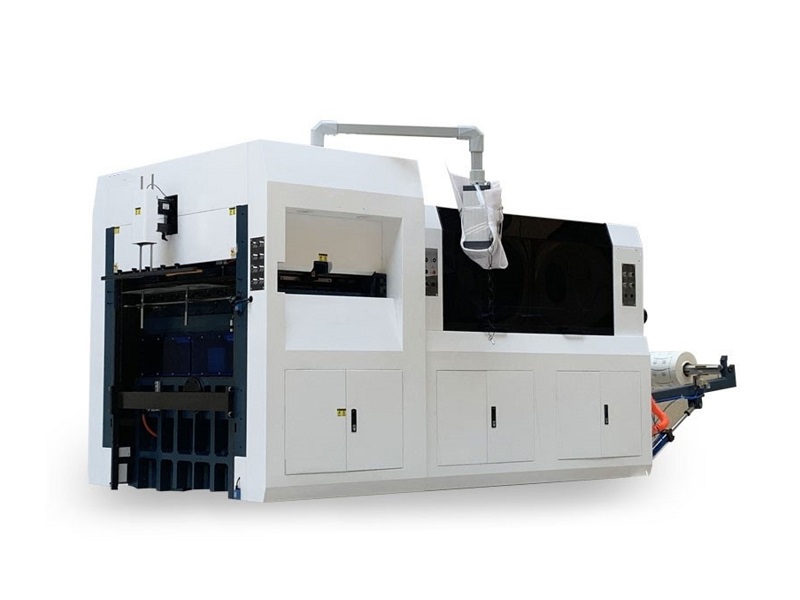

ROLLCUT

ROLLCUT is suitable for indentation, die-cutting various cigarette case, kit, paper bowl, food packaging and various paper products. Create precision die cutting all kinds of high-end paper creasing

Learn MoreCo-Extrusion Lamination Machine SPLM1300/1700

It is designed at 210m/min line speed for flexible packaging films application. It works with LDPE, PP, EVA, EAA and acid copolymers at stable and high output rate.

Learn MorePaper Straw Packing Machine PSP-02

It is used to pack beverage straws into bags automatically with three-sided seals. The whole machine is composed of driving motor, transmission system, paper unwinding device, straws filling device, automatic sealing device, finished product conveying device and so on. It has a high degree of automation and production speed. Printing, filling and packaging are completed at one time.

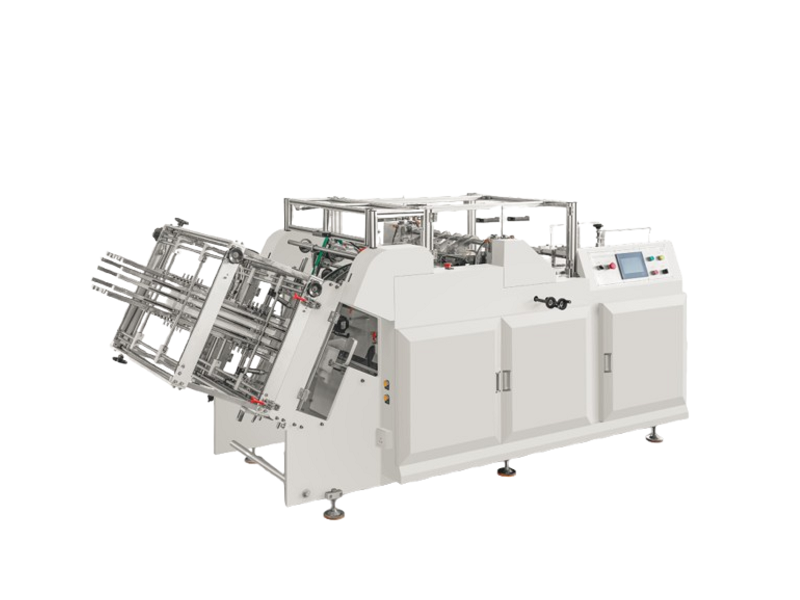

Carton Erecting Machine LT800

New-generation three-dimensional box machine is molding equipment specialized in producing various paper products, which can produce hamburger box, square box, food box (portable outside), and other boxes made by paperboard and corrugated paper, brochures, package boxes, hand-bags, etc.

Learn More