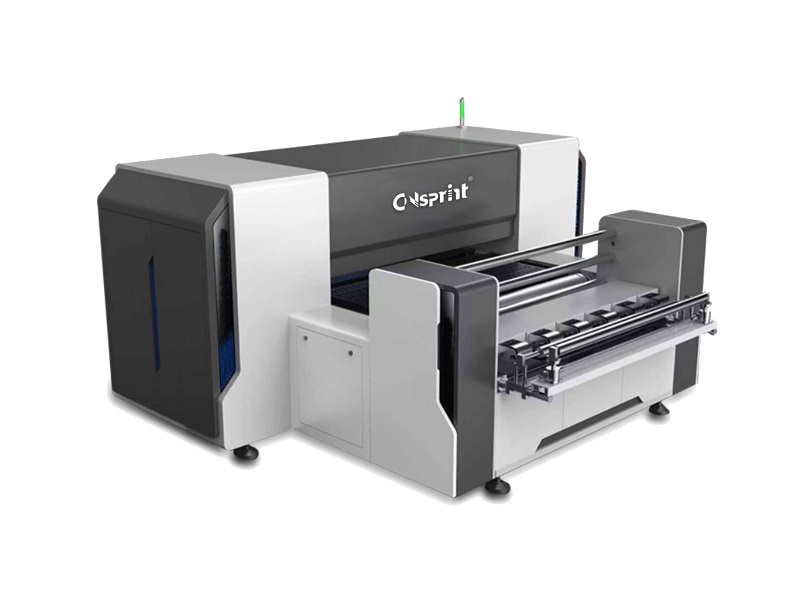

Flat Bed Cutting Plotter

Infrared sensing system, 360° surround security to ensure operator safety. Perfect camera positioning system, support ‘●’or ‘+’mark etc., improve work efficiency. The sturdy aluminum honeycomb platform has a good suction effect, ensuring that the platform is flat and not deformed after prolonged use

Features

● Infrared sensing system, 360° surround security to ensure operator safety

● Perfect camera positioning system, support ‘●’or ‘+’mark etc., improve work efficiency

● The sturdy aluminum honeycomb platform has a good suction effect, ensuring that the platform is flat and not deformed after prolonged use

● Flexible tooling system

● Efficient anti-drying and rolling feeding system, complete feeding and cutting in 5 seconds; make the machine realize continuous cutting automatically

● Powerful CAD editing and design software, perfect work with CorelDraw, Adobe illustrator, Onyx, Caldera, PrintFactory, MainTop software etc.; And support barcode reading for avoiding operator send the wrong cutting file, improve work efficiency

● The parameter formulation system can adjust the optimal cutting parameters according to different materials to ensure the precision of each cutting

● The overall frame structure, designed by senior engineers in the industry, simple, stable, easy to install and carry

● Accurate tool setting system, easy to operate, can accurately control the depth of the knife and extend the use time of mat

● Scientific and simple wiring system and chassis circuit design, stable and safe; equipped with all tool interfaces to support subsequent upgrade; easy to installation and maintenance

Technical Parameters

|

Model |

FBC2516 |

|

Working Area(mm) |

2500*1600mm |

|

Special Size |

Customizable |

|

Safe Device |

Physical anti-collision mechanism + infrared induction anti-collision to ensure production safety |

|

Cutting Tool |

EOT, UCT, KCT,CCD, Cursor, Pen, POT, DRT, PRT, CT, VCUT, URT |

|

Cutting Thickness |

≤40mm |

|

Cutting Speed |

≤1200mm/s |

|

Cutting Precision |

≤0.1mm |

|

Repeated Accuracy |

≤0.05mm |

|

Fixing Method |

Vacuum suction |

|

Interface |

Ethernet port |

|

Driving System |

Intelligent digital control servo system |

|

Command |

DXF, HPGL compatible format |

|

Control Panel |

Multi-language LCD touch panel |

|

Suction Power |

3kW~12kW(Variable frequency air pump) |

|

Power Supply |

AC220/380V 50~60Hz |

|

Working Environment |

Temperature: -10° ~ 40° Humidity: 20%~80% |

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

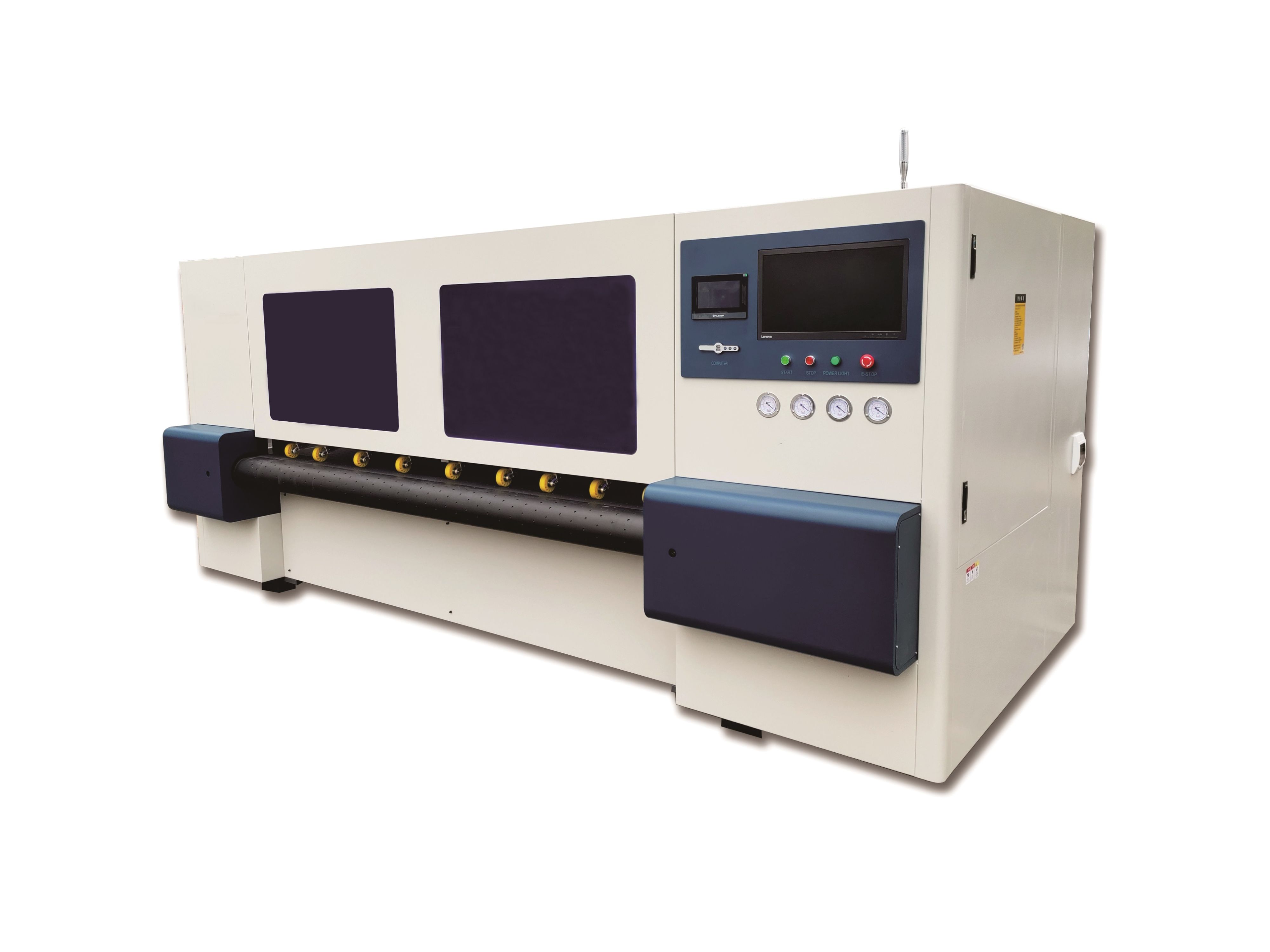

JetCarton single pass

It is an single pass industrial digital printing system for corrugated cardboard. It offers eco-friendly water-based inks suitable for corrugated cardboard. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of JetCarton single pass. The JetCarton single pass can be online with friction feeder.

Learn MoreSprintJet

The SprintJet is an single pass digital printing system for corrugated cardboard, handbag, paper cup, paper bag, label and other substrates. It offers eco-friendly water-based inks suitable for food packaging printing. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of SprintJet Series. SprintJet can be online with friction feeder.

Learn MoreFlat Bed Cutting Plotter

Infrared sensing system, 360° surround security to ensure operator safety. Perfect camera positioning system, support ‘●’or ‘+’mark etc., improve work efficiency. The sturdy aluminum honeycomb platform has a good suction effect, ensuring that the platform is flat and not deformed after prolonged use

Learn MoreJetCarton 2500

The JetCarton 2500 is an industrial digital printing system for corrugated cardboard and other substrates. It offers eco-friendly water-based inks suitable for food packaging printing. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of JetCarton 2500.The JetCarton 2000 can be online with friction feeder.

Learn More