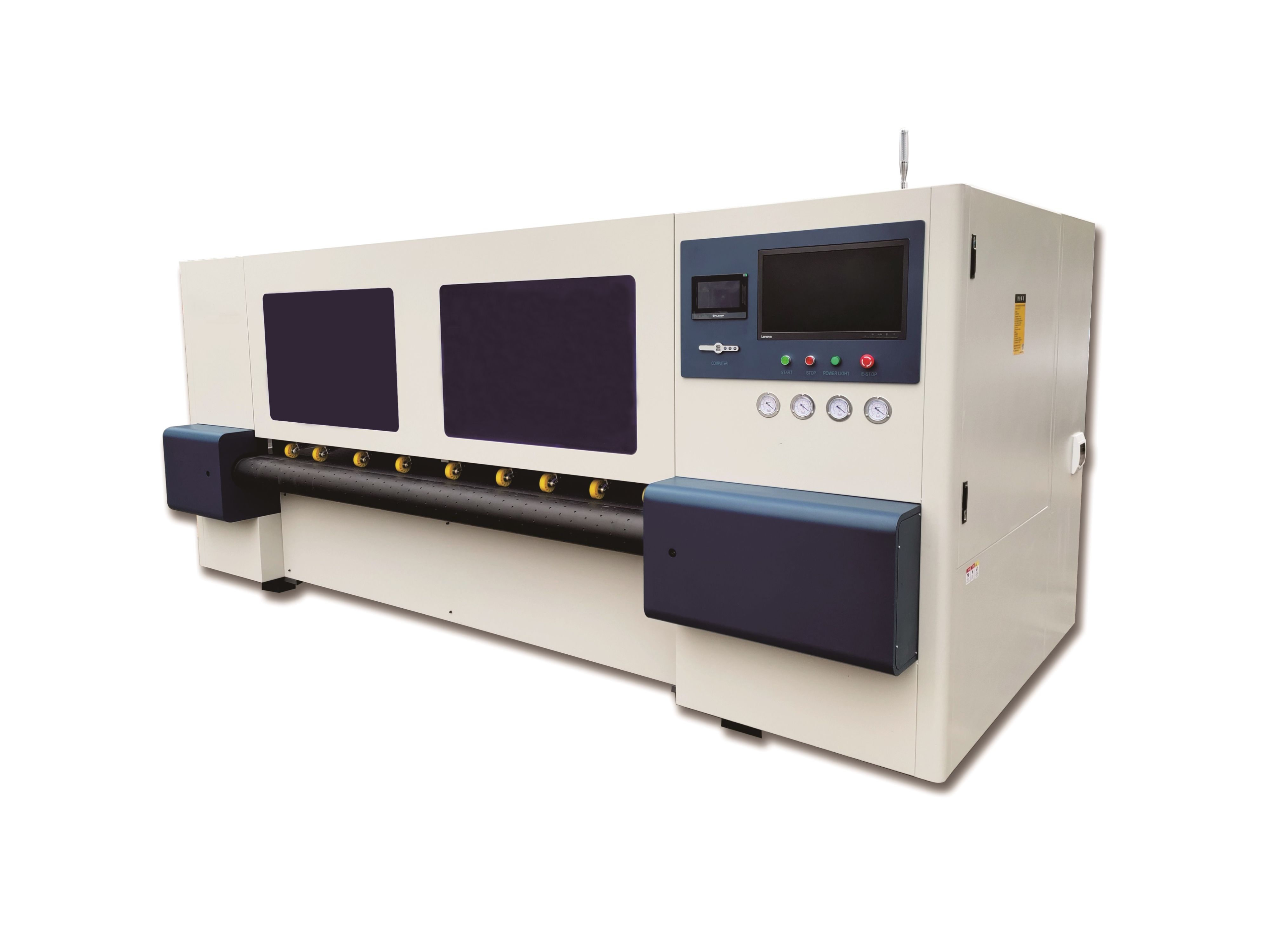

JetCarton 2500

The JetCarton 2500 is an industrial digital printing system for corrugated cardboard and other substrates. It offers eco-friendly water-based inks suitable for food packaging printing. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of JetCarton 2500.The JetCarton 2000 can be online with friction feeder.

Introduction

The JetCarton 2500 is an industrial digital printing system for corrugated cardboard and other substrates. It offers eco-friendly water-based inks suitable for food packaging printing. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of JetCarton 2500.The JetCarton 2000 can be online with friction feeder.

Technical Parameters

|

Type |

JetCarton 2500 |

|

Printhead Quantity |

8 |

|

Feeding Width |

2500mm |

|

Color Type |

C, M, Y, K |

|

Printhead Model |

EPSON I3200 |

|

Printing Speed |

1 PASS Max. 700 m2/hour |

|

Controlled Ink Dot Size |

Min 2.5PL |

|

Print Precision |

Min 360×600 DPI |

|

Corrugated Thickness |

2~16mm |

|

Platform |

Multi wind zone full adsorption paper feeding and printing platform |

|

Feeding Mode |

Automatic feeding |

|

Graphics Format Support |

JPG、BMP、TIF |

|

Ink-provide |

Fully enclosed automatic ink supply system. |

|

Work Environment |

15-32℃ indoor, temperature , Humidity 20-70% |

|

Warranty |

12 months for the machine (Including printing head ) |

|

Operate System |

Windows 7 system 64-bit operating system |

|

Power Supply |

≤ 8KW , AC 220V±10%,50-60Hz |

|

Machine Dimension |

4150×2200×1800mm |

|

Net Weight |

2300kg |

Finished Product

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

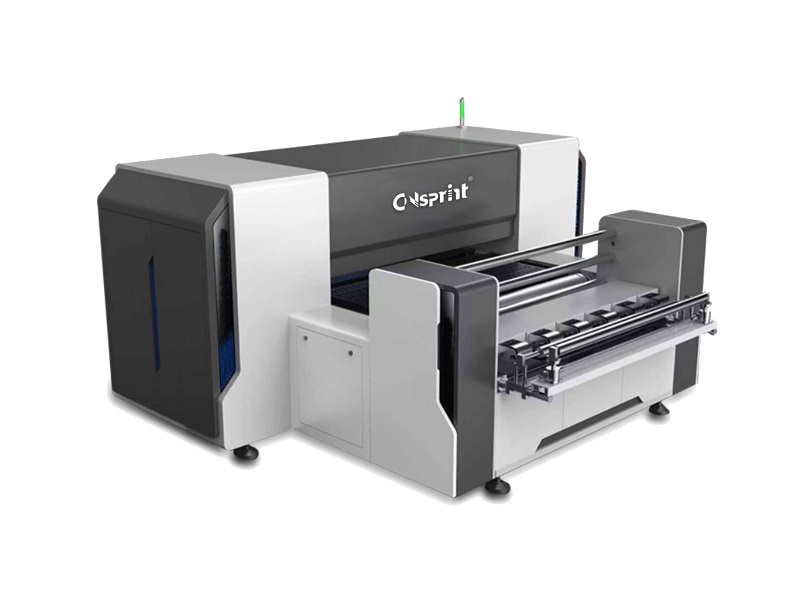

SprintJet

The SprintJet is an single pass digital printing system for corrugated cardboard, handbag, paper cup, paper bag, label and other substrates. It offers eco-friendly water-based inks suitable for food packaging printing. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of SprintJet Series. SprintJet can be online with friction feeder.

Learn MoreUV FLATBED

It is widely used in a variety of personalized gifts, glass, boards, mobile phone case, acrylic, aluminum, PVC etc. Especially it can print cylindrical gifts

Learn MoreFlat Bed Cutting Plotter

Infrared sensing system, 360° surround security to ensure operator safety. Perfect camera positioning system, support ‘●’or ‘+’mark etc., improve work efficiency. The sturdy aluminum honeycomb platform has a good suction effect, ensuring that the platform is flat and not deformed after prolonged use

Learn MoreJetCarton single pass

It is an single pass industrial digital printing system for corrugated cardboard. It offers eco-friendly water-based inks suitable for corrugated cardboard. It eliminates traditional processes such as plate making, prep and ink mixing, resulting in huge savings in time, ink, labor, plates and associated storage costs. With the intuitive touch screen and a simplified system, in a few seconds the equipment is ready for a new work configuration. On-demand printing, no ink waste, less ink consumption, environment and ease of use are some of the benefits of JetCarton single pass. The JetCarton single pass can be online with friction feeder.

Learn More