Paper Cup/Bowl Machine

It is designed to make PE/ PLA/ Biodegradable Water-based Barrier Coating cups/ bowls for fast drink / food packages

Introduction

It is designed to make PE/ PLA/ Biodegradable Water-based Barrier Coating cups/ bowls for fast drink / food packages

Technical Parameters

| Model | PCM100 | PCM200 | PCM300 | PCM400 |

| Paper Range (gsm) | 170-350 | 180-350 | 210-350 | 210-350 |

| Cup Size (oz) | 4-32 | 16-46 | 28-120 | 16-200 |

| Speed (pcs/min) | 120-150 | 80-120 | 60-85 | 50-70 |

| Power Consumption (kW) | 21 | 25 | 32 | 32 |

| Air Consumption (at 6kg/cm2) | 0.4 m³/min | 0.4 m³/min | 0.4 m³/min | 0.4 m³/min |

| Dimensions L × W × H (mm) | 2820×1300×1850 | 2820×1450×1850 | 3020×1600×1850 | 3800×1700×1850 |

| N.W. (kg) | 4200 | 4800 | 5200 | 5800 |

Finished Product

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

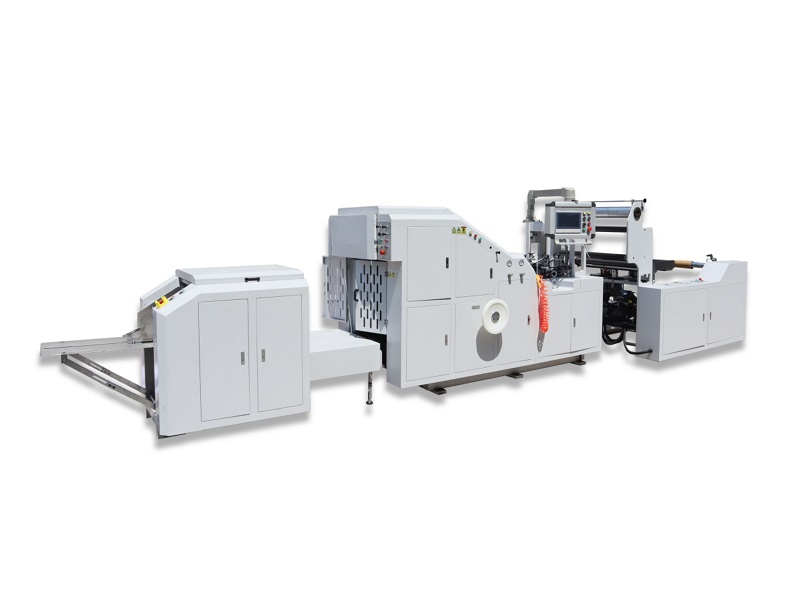

Square Bottom Paper Bag Making Machine

This roll fed flat handle paper bag making machine is designed for printing roll paper, including primary color paper and kraft paper, as well as completing the production of paper rolls such as food paper in a single process. It offers automatic center gluing, raw material tube formation, length cutting, bottom indentation, and bottom folding. The roll fed flat handle paper bag making machine also applies glue to the bottom and shapes the bottom of the bag. With its convenience, efficiency, and stability, this environmentally friendly paper bag machine produces various types of paper bags, including snack food bags, bread bags, and dried fruit bags, providing a comprehensive bag finishing solution.

Learn MoreCo-Extrusion Lamination Machine

It is designed at 210m/min line speed for flexible packaging films application. It works with LDPE, PP, EVA, EAA and acid copolymers at stable and high output rate.

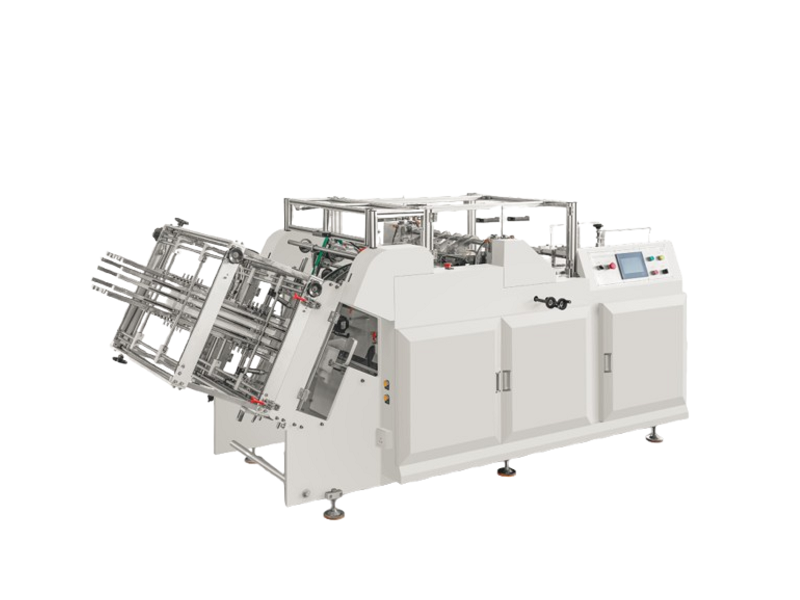

Learn MoreCarton Erecting Machine LT800

New-generation three-dimensional box machine is molding equipment specialized in producing various paper products, which can produce hamburger box, square box, food box (portable outside), and other boxes made by paperboard and corrugated paper, brochures, package boxes, hand-bags, etc.

Learn MorePaper Straw Packing Machine PSP-02

It is used to pack beverage straws into bags automatically with three-sided seals. The whole machine is composed of driving motor, transmission system, paper unwinding device, straws filling device, automatic sealing device, finished product conveying device and so on. It has a high degree of automation and production speed. Printing, filling and packaging are completed at one time.