Paper Plate Machine SPP600/800

This layout: transmission unit under the working table and moulds above the working table are applied on the SPP600/800. Keep the transmission unit and moulds separate is more convenient for operator to clean and maintain. The whole working process: paper feeding, forming, dish ejecting, temperature constant controlling is fully automatic. It is specialized in producing round shaped, square shaped and irregular shaped paper plates.

Introduction

This layout: transmission unit under the working table and moulds above the working table are applied on the SPP600/800. Keep the transmission unit and moulds separate is more convenient for operator to clean and maintain. The whole working process: paper feeding, forming, dish ejecting, temperature constant controlling is fully automatic. It is specialized in producing round shaped, square shaped and irregular shaped paper plates.

Technical Parameters

| Model | SPP600 | SPP800 |

| Paper Plate Size (mm) |

Round Shaped: Φ100-320 Square Shaped: Max. 350(L)×300(W) |

Round Shaped: Φ100-420 Square Shaped: Max. 450(L)×400(W) |

| Working Station Number | 2 | 1 |

| Producing Speed ( pcs/min) | 50-120 | 15-20 |

| Weight (kg) | 1600 | 2000 |

| Dimenison L×W×H (mm) | 3500×1300×2000 | 2500×1300×2200 |

| Paper Range | 100-800g/m2 (original paper, white paperboard,white cardboard, aluminum foil paper or others) | 100-3500g/m2 (original paper, white paperboard, white cardboard, aluminum foil paper or other heavy gsm paper) |

| Hydraulic Pressure | 0.3-0.6Mpa | 0.3-0.6Mpa |

| Air Source | Working Pressure: 0.4Mpa Air Volume: 0.3m3/min | Working Pressure: 0.4Mpa Air Volume: 0.3m3/min |

| Power Requirements | 380V 50/60Hz 3P | 380V 50/60Hz 3P |

| Total Power Consumption (kW) | 8 | 8 |

Finished Product

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Flexo Printer

This machine is mainly used for printing on PE-coated paper, cup paper rolls, food packaging paper, and kraft paper. It is ideal for producing paper cup fans, food boxes, and other paper-based packaging products.

Learn MorePaper Box Forming Machine PACKFOOD 1C/2C

Disposable paper boxes are commonly seen in ordinary life, bringing convenience to people all over the world. Our disposable paper box forming machine features advantages such as high productivity, attractive appearance, easy operation, save maintain cost, lower occupied area, compact structure, strong frame, low noise, etc.

Learn MorePaper Straw Making Machine PSM8-SS

Itintegratesfeeding, gluing, winding, cutting, conveying andcollecting. It is equipped with CNC multi-knife cutting system. It is suitable for 5-12mm diameter paperstraw.

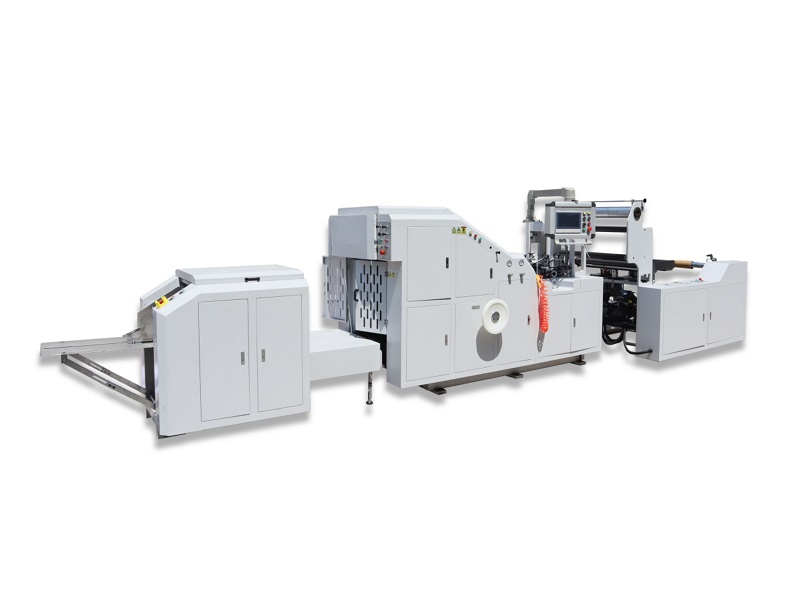

Learn MoreSquare Bottom Paper Bag Making Machine

This roll fed flat handle paper bag making machine is designed for printing roll paper, including primary color paper and kraft paper, as well as completing the production of paper rolls such as food paper in a single process. It offers automatic center gluing, raw material tube formation, length cutting, bottom indentation, and bottom folding. The roll fed flat handle paper bag making machine also applies glue to the bottom and shapes the bottom of the bag. With its convenience, efficiency, and stability, this environmentally friendly paper bag machine produces various types of paper bags, including snack food bags, bread bags, and dried fruit bags, providing a comprehensive bag finishing solution.

Learn More