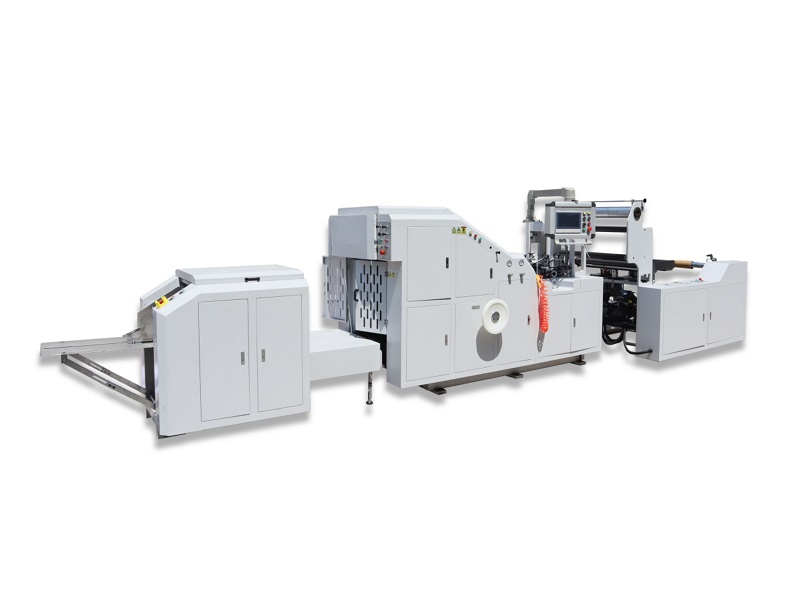

Box Wrapper SPYD-450H

Automatic mould adjusting to satisfy producing different size box

Adjust mould without changing blister plate and blade for shortening the adjusting time half (It just cost 10-15min. For old version, it will cost 20-30min)

Fold ears, wrap, insert and form the box automatically in one lot

Feature

Automatic mould adjusting to satisfy producing different size box

Adjust mould without changing blister plate and blade for shortening the adjusting time half (It just cost 10-15min. For old version, it will cost 20-30min)

Fold ears, wrap, insert and form the box automatically in one lot

Driven by servo motor and PLC control

With Weinview touch screen interface

With AirTAC cylinder and Taiwan Brand guide rail

Equipped with protectors to ensure the safety of the operator

Equipped with brush wheel for folding sides smoothly

Equipped with air pressure detector on the box inserter. The machine can’t run if the box are not inserted or inserted wrongly

The bottom mould is pneumatic drive to prevent bubble generation

Technical Parameters

|

Model |

SPYD-450H |

|

Min.Box Size |

50*50*10mm |

|

Max. Box Size |

400*450*130mm |

|

Production Speed |

15-20pcs/min |

|

Power Consumption |

2.2kW |

|

Input Air Pressure |

0.6Mpa |

|

Dimension |

1500*1050*2100 |

|

Weight |

800kg |

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

PP STRAP

PP STRAP strapping machine is suitable for the strapping and packing of conventional objects and all kinds of cartons

Learn MoreSquare Bottom Paper Bag Making Machine

This roll fed flat handle paper bag making machine is designed for printing roll paper, including primary color paper and kraft paper, as well as completing the production of paper rolls such as food paper in a single process. It offers automatic center gluing, raw material tube formation, length cutting, bottom indentation, and bottom folding. The roll fed flat handle paper bag making machine also applies glue to the bottom and shapes the bottom of the bag. With its convenience, efficiency, and stability, this environmentally friendly paper bag machine produces various types of paper bags, including snack food bags, bread bags, and dried fruit bags, providing a comprehensive bag finishing solution.

Learn MoreFour Side Folding Case Maker

This machine is mainly applied in covering and pressing various notebooks, photo books (photo album), folders, certificates, hardcover books. This process is finished easily fold four sides at the same time by one operator. It is the good partner of post-press, especially the digital post-press.

Learn MoreBox Wrapper SPYD-450H

Automatic mould adjusting to satisfy producing different size box

Adjust mould without changing blister plate and blade for shortening the adjusting time half (It just cost 10-15min. For old version, it will cost 20-30min)

Fold ears, wrap, insert and form the box automatically in one lot